Exclusive Service 01

Liner Hanger Systems 02

Frac & Isolation Tools 03

Toe Initiation Tools 04

Exclusive Service 01

We design and deliver advanced completion systems that improve well integrity, stimulation efficiency, and production performance.

Our engineering teams develop and field-test completion hardware and support systems – from liner hangers and multi-stage sleeve assemblies to frac plugs, cementing tooling, and flow-control devices – engineered for reliable deployment and predictable performance in complex well environments. Through precise tool design, rigorous testing, and experienced wellsite execution, we help operators reduce NPT, simplify interventions, and maximize recovery across the completion lifecycle.

Liner Hanger Systems 02

We provide field-proven liner hanger systems that enhance completion precision, minimize operational risks, and improve well performance – even in complex environments.

Our systems combine advanced anchoring and sealing technologies to ensure secure liner installation, reliable annular isolation, and long-term well integrity. Engineered for efficiency and durability, they deliver consistent performance across a full range of completion challenges.

Frac & Isolation Tools 03

We design multi-stage sleeve completion systems that optimize stimulation efficiency, ensure precise zonal isolation, and deliver reliable performance in both cased and openhole wells.

Our systems are engineered for flexibility and durability, enabling faster stimulation cycles, reduced non-productive time, and improved recovery. Built on advanced technology and field-proven design, they provide consistent results across a wide range of unconventional and complex well environments.

Toe Initiation Tools 04

We provide reliable toe initiation systems that enable controlled and efficient stimulation initiation without the need for tubing-conveyed perforating.

Our portfolio includes immediate and delayed open toe sleeves and wet shoe subs engineered for precise pressure activation and dependable first-stage initiation. Designed for simplicity, reliability, and cost efficiency, these tools ensure faster stimulation cycles, reduced non-productive time, and consistent performance across a wide range of well conditions.

Cementing Equipment 05

Cementing Equipment 05

We provide advanced cementing equipment engineered to ensure well integrity, effective zonal isolation, and reliable fluid loss control — even in complex well conditions.

Our systems deliver precise cement placement and long-term sealing performance to support safe and efficient well construction. Designed for reliability and cost-effectiveness, they help operators mitigate risks such as sustained casing pressure and achieve consistent results across the full range of cementing applications.

Production Systems 06

Production Systems 06

We offer advanced production systems designed to minimize formation damage and enhance well productivity throughout completion and workover operations.

Our proprietary DEFENDER™ formation protection valve, used with the Production Stinger, provides controlled flow, improved wellbore safety, and seamless integration with ESP systems.

Engineered for reliability and efficiency, these solutions ensure stable production, protect against backflow, and simplify retrieval – delivering consistent performance and long-term well integrity.

Supporting Completion Tools & Flow Control Systems 07

Supporting Completion Tools & Flow Control Systems 07

We provide a comprehensive suite of completion and flow control tools designed to enhance operational efficiency, maintain well integrity, and support sustained production performance.

Our portfolio includes cement retainers, flow control devices, and completion accessories engineered for reliable operation in diverse well conditions. These tools enable precise zone isolation, controlled inflow, and optimized string configuration, delivering consistent, dependable performance across every stage of the completion process.

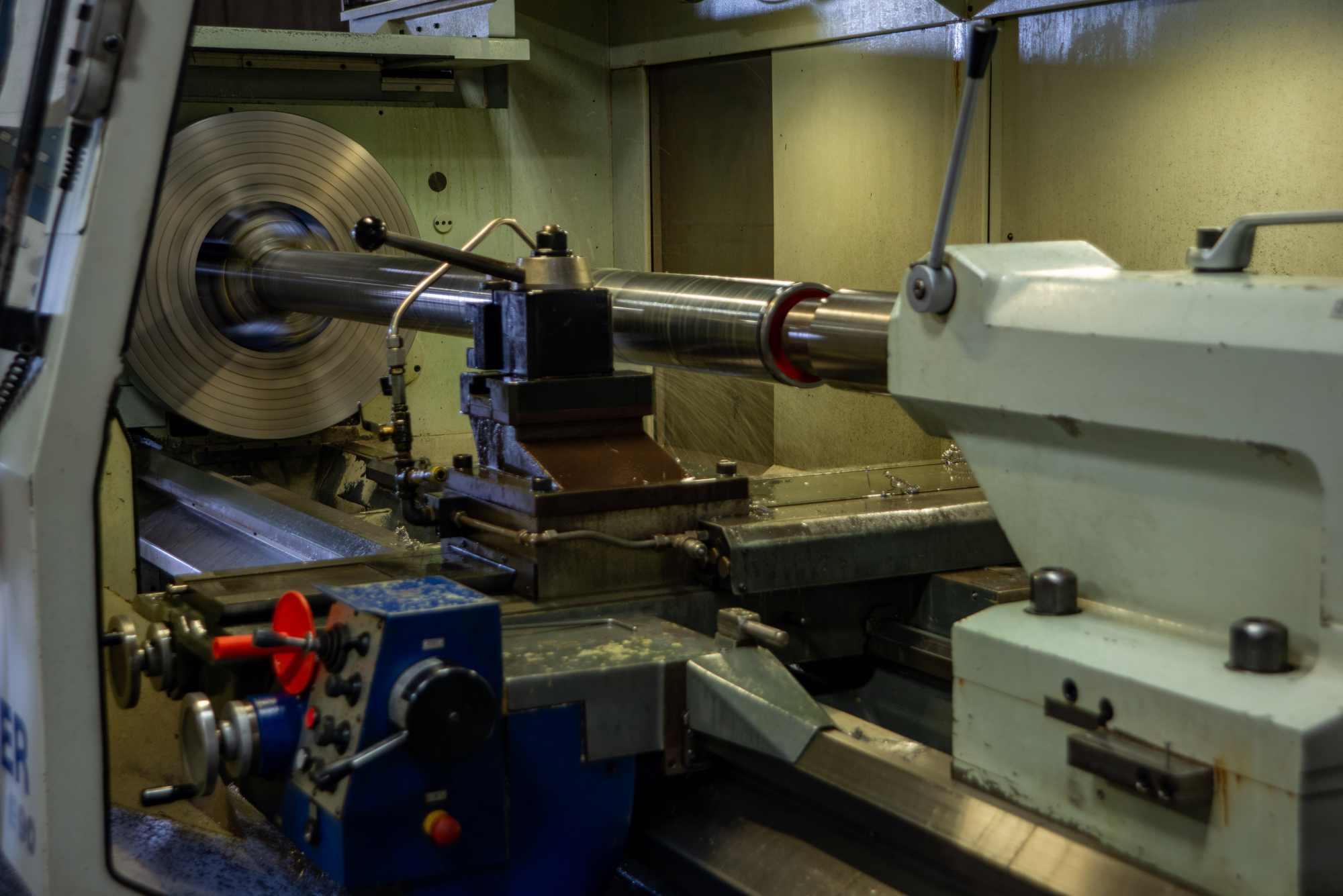

Engineering & Custom Solutions 08

We deliver tailored engineering and custom solutions that address complex completion challenges with precision and efficiency.

Gallery 08

Contact 09

Frontier International LLC

Houston

Phone:

+1-832-912-5929Fax:

+1-832-912-5929Email:

frontier@fr-intl.com